A cornucopia, or horn of plenty, is commonly depicted as a large horn-shaped container overflowing with fruits, flowers or coins. 3D-printing has often been compared to the ancient symbol of abundance and wealth. Will it provide a spectacular new opportunity for production, or open a Pandora’s Box of piracy? The technology provides an opportunity to re-examine old assumptions about how production should work. The answer lies in the role of markets. The promise of the internet revolution was to provide everyone with all available knowledge. The promise of the 3D-printer revolution is to provide us with an abundance of material goods. Visions abound of limitless replication – printing machine components, clothes, musical instruments, and even body parts.

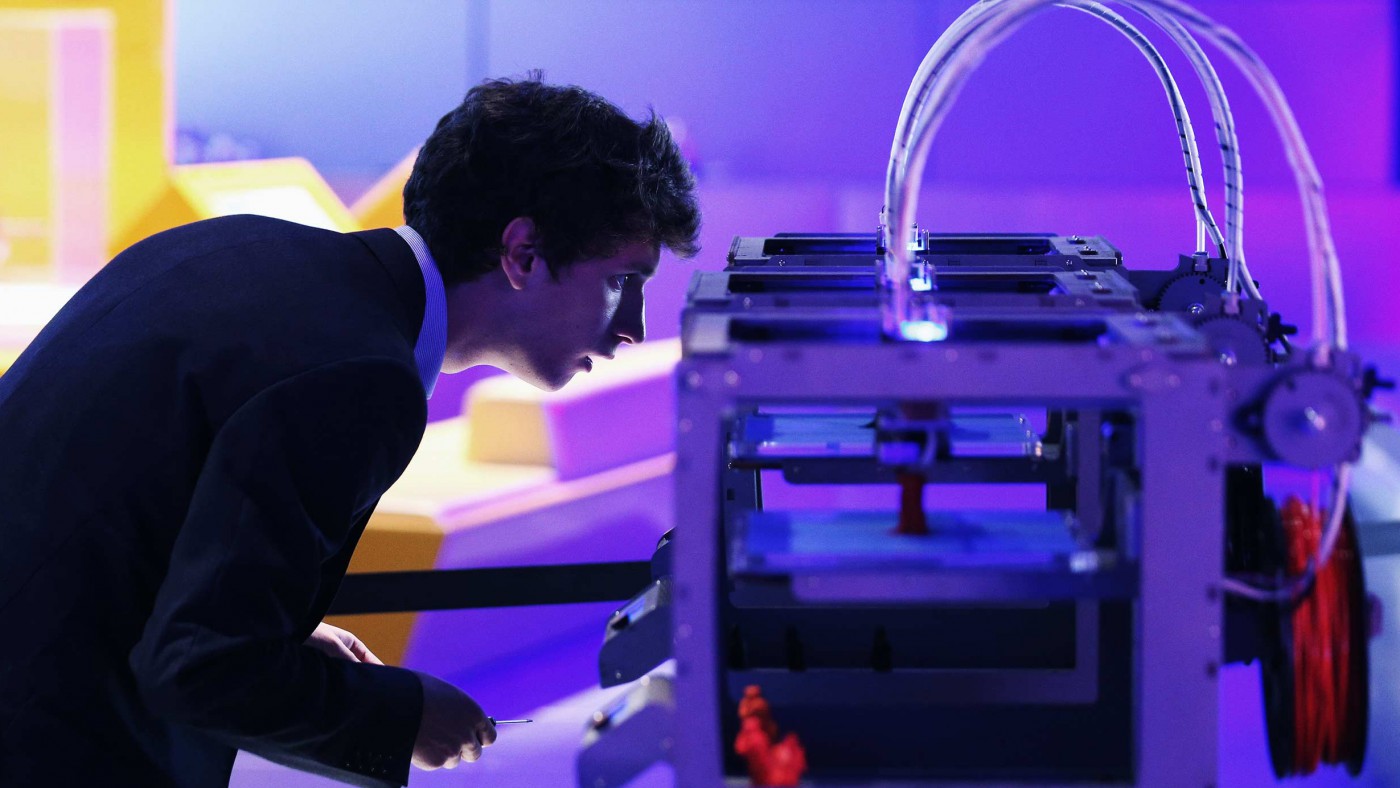

3D printing is becoming increasingly productive, affordable and accessible, but it is actually not a particularly new line of technology. In manufacturing, Computer Numerical Control (CNC)- systems have been around since the 1950s controlling lathes, milling machines and laser cutters. In modern CNC systems, end-to-end component design is already highly automated, using computer-aided design (CAD) and computer-aided manufacturing (CAM) programs.

The 3D-printer works on the same principle, but adds to this the reproducible ability of software. Nicholas Negroponte, the founder of MIT’s media lab, discussed the blurring of bits and atoms already in back 1995 in his book ”Being Digital”. Negroponte argued that all forms of information made up of atoms would be transformed into bits. With information being fully storable and transferrable, specialised devices would converge into multipurpose tools.

The smartphone is a good example of Negroponte’s thoughts, as it works as a computer, a video player, an MP3 player, a camera, a calculator, a notebook, and of course as a telephone. Negroponte also foresaw that information would bridge the divide between dead and living matter. The synthetic and the natural worlds would converge, leading to the printing of living tissue for organ transplantations. The first hype of the 3D-printers peaked about a year ago. Headlines promising restored manufacturing have become less common.

Today’s 3D printers primarily work with soft and malleable material. They can print the most intricate or simple shapes with equal ease, while traditional technologies struggle with geometrical complexity. Objects made out of more than one material are more difficult to print. The resolution and quality of 3D printers need to be improved for industrial use. CAD and CAM and user-friendly technology lowers the thresholds for the user, but do not replace prior knowledge and skill entirely. While 3D printing may be hindered by complexity, volume and speed are constraints for their use in manufacturing. The most important progress so far has been in reducing the high costs of building prototypes.

The 3D-printer’s connection to the web means that political debate on copyright and patents will intensify. Designs could be downloaded and produced regardless of intellectual property. After all, the way computer technology distributes content is by copying it, exactly what copyright legislation defines as an infringement. Will creators face sites, similar to the notorious Pirate Bay, or be forced into doing business with channels such as Spotify?

On the other hand, there is a risk that incumbents defend their market position against competitors using 3D-printer by extending the reach of copyright. Political support could be easy to gather as it is often difficult to pinpoint reasons for losses, reduced sales and unemployment, thus using 3D-printing as a scapegoat. The American Digital Millennium Copyright Act has served as a model for many legislations, putting the responsibility for a breach with the hosting site. The rights-holders must request the hosting site to remove a specific infringing file, a DMCA takedown notice, leaving the host just as an impartial communicator between the rights-holder and the uploader.

In fact, the first takedown notice for a 3D-printer design has already been issued. Many of the concerns voiced by IP-skeptics are the concerns of creators too. There is a need to prevent abuse, such as trivial patents that are granted too easily, patents with prior art or drawn out and uncertain legal processes. Protecting the interests of rights-holder, while at the same time providing a variety options for the public probably involves keeping many models generic as aesthetic qualities make them easier to claim for copyright. At present, laws often strive to sever the specific features that can be copyrighted from the rest of the object. Those limits to the legal protection of physical goods will probably become more sharply delineated.

Economist Friedrich Hayek saw knowledge, creativity, and technology charged with strong personal sentiments and ideas. He argued against the position that technology is value-free. In his essay ”The Use of Knowledge in Society” he argued that the adoption of technology is best seen a process of negotiations, a marketplace of ideas. Tacit knowledge such as guesses, hunches and personal visions are as decisive as informed, committed actions in determining how a specific technology will be applied.

Modern technology is enclosed and expert-driven. It is user friendly, but its ”Black box design” is not open to adaptation or changes. The maker movement, a globally scattered community of DIY enthusiasts, hacks, researchers, designers and contractors, making everything from embroidery to robotics, show a different way, working through generic designs, open code and rented 3D-printers. Studying their efforts reflects Hayek’s view of local knowledge doing the best of a new innovation.

The web interconnects these local marketplaces of ideas. The first impact of globalization resulted in large companies moving production to where it was cheapest. Technology and free trade would eventually overcome cultural barriers and geographical limitations. But the rising prices of energy and the economic downturn puts pressure on fragile production concepts as “lean production” and “just in time”. Integrated logistical supply chains are vulnerable to disruptions, entailing high costs. The requirements for precision and efficiency in production means that certain types of production previously outsourced, may return to Europe. Investments are made in countries that provide good infrastructure and large markets.

We could begin to see a revival of manufacturing in the United States and Europe, centred around cottage industries of small companies using high-tech 3D-printers. But work on the assembly lines will require more advanced vocational training, to raise the competitiveness of semi-skilled workers against this oncoming wave of automation.